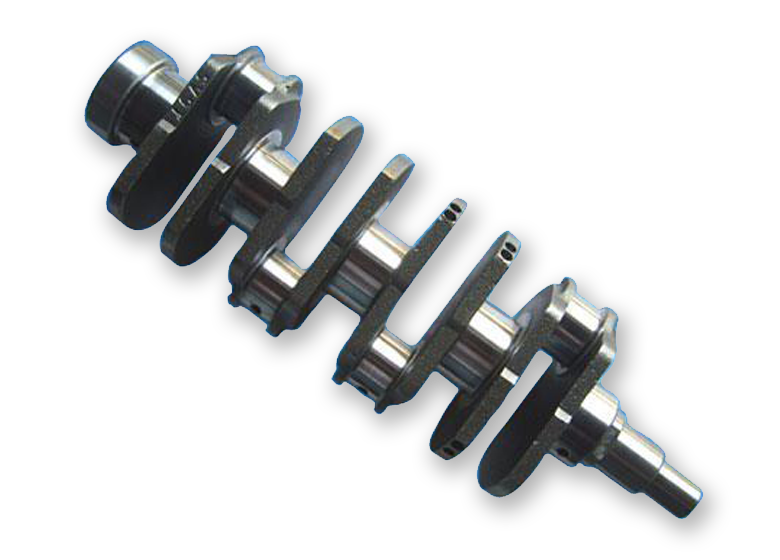

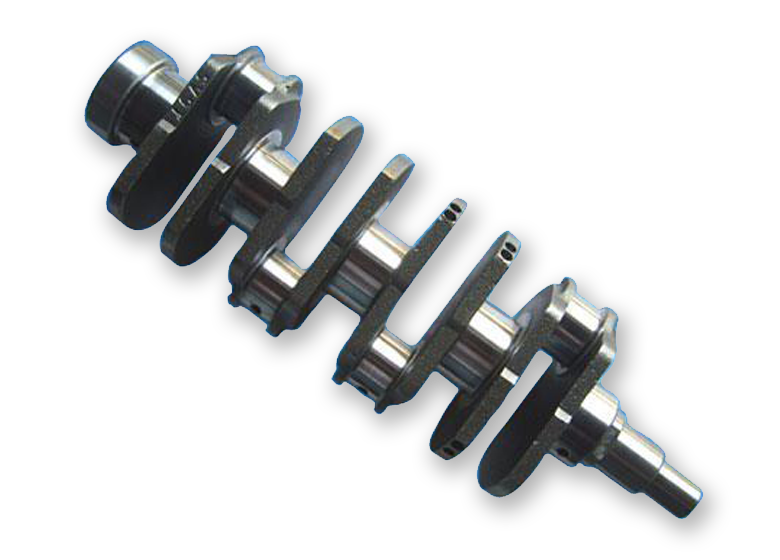

Among the thirty-six machining processes of automotive engine crankshafts, crankshaft dynamic balance machining is listed as a key machining process. Poor precision in dynamic balance machining can lead to excessive vibration during vehicle operation, affecting driving stability and even causing crankshaft fracture and safety accidents. The development of dynamic balance testing technology and signal processing technology is rapid. Although a series of detection adjustments and comparisons have been made in machining, the dynamic balance stability of the crankshaft is still not good enough. Further investigation is needed to identify the reasons for measurement stability and seek new solutions.

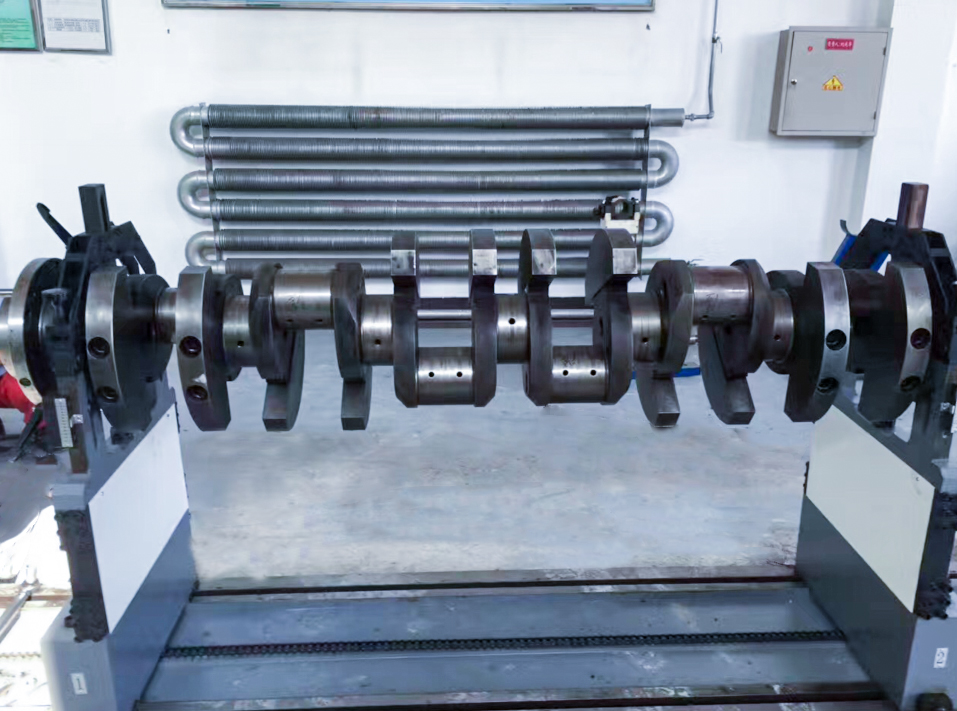

How to choose a dynamic balancing machine when performing dynamic balance testing on the crankshaft? The difference in working principles between soft support and hard support dynamic balancing machines inevitably leads to differences in their structure and operating methods, resulting in their respective advantages and disadvantages. When choosing, careful analysis is needed. Some balancing tasks must use soft support, some must use hard support, some soft support is better, and some hard support has more obvious advantages.

1. For large-scale production of light and small crankshafts, the specifications of the balanced crankshaft are generally limited, and it is generally known when purchasing a balancing machine. In this case, it is advisable to choose a soft support balancing machine. Its high sensitivity advantage can be fully utilized, and the parasitic quality impact has been controlled by the manufacturer within the range that does not affect accuracy. The limited set of calibration data can be stored in the measuring instrument, and the operator can use it as if it were a permanent calibration.

2. For large-scale production of crankshafts with a certain weight, the characteristic is that the rotor specifications are relatively small and generally known, but higher impact resistance is required. In this case, it is advisable to use a hard supported balancing machine, which works beyond the permanent calibration range and is close to the resonance zone (also known as a semi hard balancing machine). At this time, high sensitivity can be achieved, and it has the advantages of strong structure and high reliability.

3. Most of them belong to the production or maintenance of single or medium to small batch crankshafts, and the rotor specifications that need to be balanced are diverse and cannot be determined in advance. In this case, a universal crankshaft dynamic balancing machine is needed. At this point, the hard support balancing machine has its unique advantages. Its advantages such as permanent calibration, allowing for larger initial unbalance, and high reliability are fully utilized.

Shanghai Shenman advocates learning from the mechanical design and production concepts of Germany and Japan. We now have a professional technical research and development team, which can improve and transform the equipment technology based on the existing dynamic balancing machines of users. We can also provide customized non-standard dynamic balancing machines according to the special workpiece needs of users.

The core components of the dynamic balance equipment at Shenman Dynamic Balance Machine Factory are made of high-quality electronic components and imported components, which better ensure the stability and service life of the dynamic balance equipment, and better ensure the high standard requirements of product quality. Localized production has better reduced the transportation and maintenance costs of imported equipment, and also enabled users to purchase the most practical products with the most economical effort, making our products more competitive in the market. If you need a dynamic balancing machine, please feel free to contact our technical customer service for consultation.

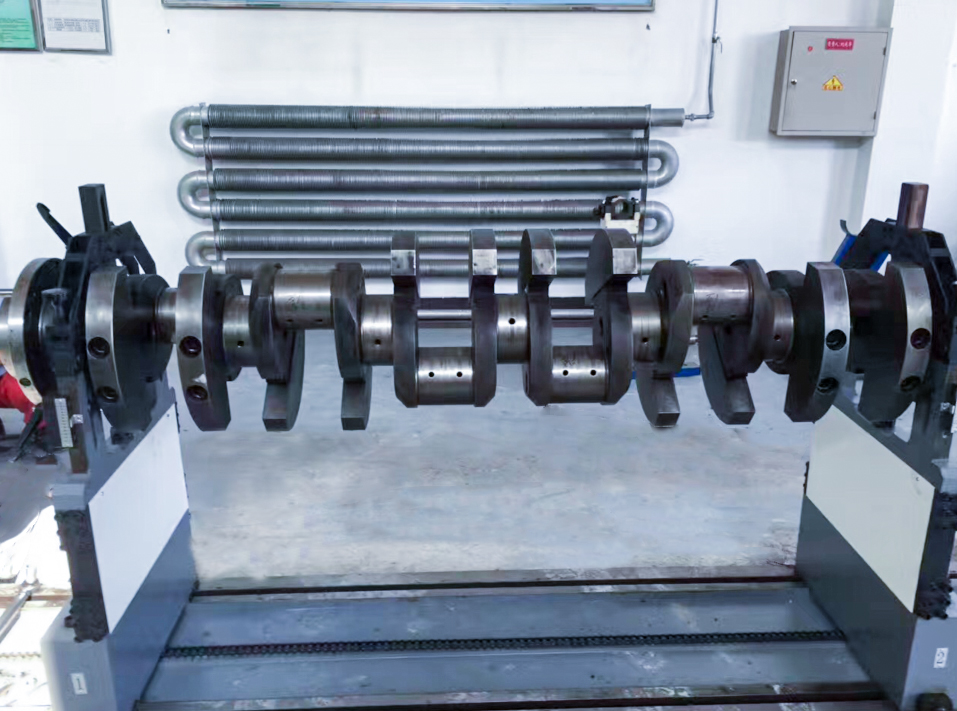

How to choose a dynamic balancing machine when performing dynamic balance testing on the crankshaft? The difference in working principles between soft support and hard support dynamic balancing machines inevitably leads to differences in their structure and operating methods, resulting in their respective advantages and disadvantages. When choosing, careful analysis is needed. Some balancing tasks must use soft support, some must use hard support, some soft support is better, and some hard support has more obvious advantages.

1. For large-scale production of light and small crankshafts, the specifications of the balanced crankshaft are generally limited, and it is generally known when purchasing a balancing machine. In this case, it is advisable to choose a soft support balancing machine. Its high sensitivity advantage can be fully utilized, and the parasitic quality impact has been controlled by the manufacturer within the range that does not affect accuracy. The limited set of calibration data can be stored in the measuring instrument, and the operator can use it as if it were a permanent calibration.

2. For large-scale production of crankshafts with a certain weight, the characteristic is that the rotor specifications are relatively small and generally known, but higher impact resistance is required. In this case, it is advisable to use a hard supported balancing machine, which works beyond the permanent calibration range and is close to the resonance zone (also known as a semi hard balancing machine). At this time, high sensitivity can be achieved, and it has the advantages of strong structure and high reliability.

3. Most of them belong to the production or maintenance of single or medium to small batch crankshafts, and the rotor specifications that need to be balanced are diverse and cannot be determined in advance. In this case, a universal crankshaft dynamic balancing machine is needed. At this point, the hard support balancing machine has its unique advantages. Its advantages such as permanent calibration, allowing for larger initial unbalance, and high reliability are fully utilized.

Shanghai Shenman advocates learning from the mechanical design and production concepts of Germany and Japan. We now have a professional technical research and development team, which can improve and transform the equipment technology based on the existing dynamic balancing machines of users. We can also provide customized non-standard dynamic balancing machines according to the special workpiece needs of users.

The core components of the dynamic balance equipment at Shenman Dynamic Balance Machine Factory are made of high-quality electronic components and imported components, which better ensure the stability and service life of the dynamic balance equipment, and better ensure the high standard requirements of product quality. Localized production has better reduced the transportation and maintenance costs of imported equipment, and also enabled users to purchase the most practical products with the most economical effort, making our products more competitive in the market. If you need a dynamic balancing machine, please feel free to contact our technical customer service for consultation.

36 Views