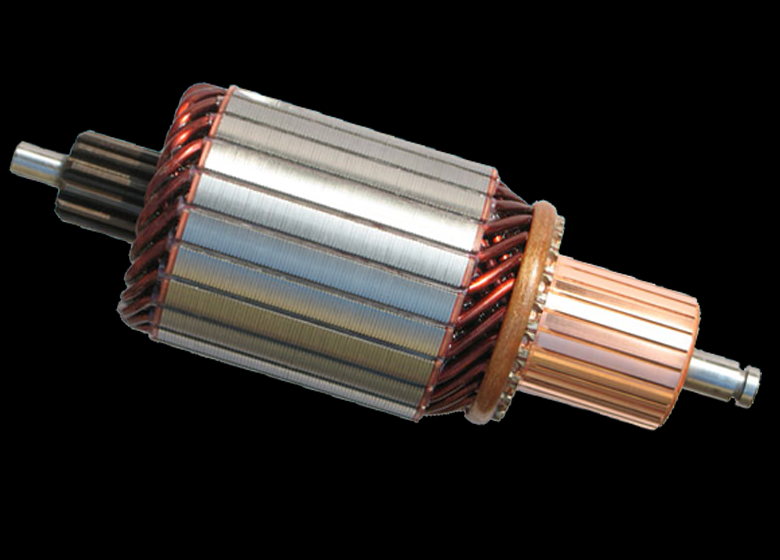

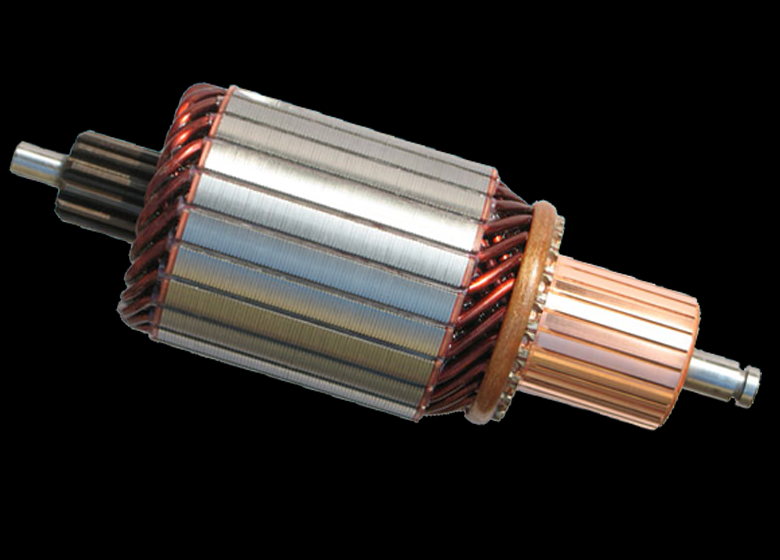

What are the effects of rotor imbalance on motor quality? In this article, the technicians from Shenman Dynamic Balancing Machine Factory mainly analyze the vibration and noise problems caused by rotor mechanical imbalance, as well as the dynamic and static imbalances of the rotor.

Usually, the imbalance of the motor rotor can be divided into static imbalance, dynamic imbalance, and mixed imbalance. The centrifugal force caused by static imbalance produces vibrations of equal magnitude and phase on two supports. The centrifugal force couple caused by dynamic imbalance produces vibrations of equal magnitude and opposite phase on two supports. The most commonly encountered issue in practice is still mixed unbalance, which is caused by the combined action of residual static unbalance centrifugal force and dynamic unbalance centrifugal force couple on two supports, resulting in vibrations of varying sizes and phases. The mechanical imbalance of the rotor can be eliminated by balancing.

1. Reasons for unbalanced vibration of the rotor: residual imbalance during manufacturing, excessive attachment of dust generated during long-term operation, shaft bending caused by thermal stress during operation, unbalanced load caused by thermal displacement of rotor accessories, deformation or eccentricity caused by centrifugal force of rotor accessories, shaft bending caused by external forces (such as belts, gears, and poor connections), poor bearing device (accuracy or locking of the shaft) causing shaft bending or internal deformation of the bearing.

2. How to suppress rotor imbalance: maintain it within the allowable imbalance, improve the excessive tight fit between the shaft and the iron core, and design improvements to address the heterogeneity of thermal expansion. Improvement of strength design or assembly, modification of shaft strength design, change of type of shaft coupling and correction of straight coupling center, prevention of deviation between bearing end face and shaft attachment section or locking nut.

3. The causes of abnormal vibration and noise in bearings include internal damage to the bearings, abnormal axial vibration of the bearings, excitation of the vibration system composed of axial spring constant and rotor mass; Poor lubrication and bearing clearance caused by cylindrical rolling bearings or large diameter high-speed ball bearings.

4. Replacement of bearings: Apply appropriate axial spring preloading to adjust the bearing clearance, choose soft grease or grease with excellent low-temperature performance, and keep the residual clearance small (pay attention to temperature rise issues).

5. Method of rotor dynamic balance correction: After conducting dynamic balance measurement on the rotor of the dynamic balancing machine, the rotor can be balanced and processed using the weighting method and weight removal method as needed. The so-called weighting method is to install correction weights in the opposite direction of imbalance. Common methods include welding, soldering, riveting, screwing, and adding weight blocks. The weight removal method is to remove a certain amount of weight in the direction of imbalance. The commonly used methods include boring, drilling, chiseling, milling, grinding, etc.

Usually, the imbalance of the motor rotor can be divided into static imbalance, dynamic imbalance, and mixed imbalance. The centrifugal force caused by static imbalance produces vibrations of equal magnitude and phase on two supports. The centrifugal force couple caused by dynamic imbalance produces vibrations of equal magnitude and opposite phase on two supports. The most commonly encountered issue in practice is still mixed unbalance, which is caused by the combined action of residual static unbalance centrifugal force and dynamic unbalance centrifugal force couple on two supports, resulting in vibrations of varying sizes and phases. The mechanical imbalance of the rotor can be eliminated by balancing.

1. Reasons for unbalanced vibration of the rotor: residual imbalance during manufacturing, excessive attachment of dust generated during long-term operation, shaft bending caused by thermal stress during operation, unbalanced load caused by thermal displacement of rotor accessories, deformation or eccentricity caused by centrifugal force of rotor accessories, shaft bending caused by external forces (such as belts, gears, and poor connections), poor bearing device (accuracy or locking of the shaft) causing shaft bending or internal deformation of the bearing.

2. How to suppress rotor imbalance: maintain it within the allowable imbalance, improve the excessive tight fit between the shaft and the iron core, and design improvements to address the heterogeneity of thermal expansion. Improvement of strength design or assembly, modification of shaft strength design, change of type of shaft coupling and correction of straight coupling center, prevention of deviation between bearing end face and shaft attachment section or locking nut.

3. The causes of abnormal vibration and noise in bearings include internal damage to the bearings, abnormal axial vibration of the bearings, excitation of the vibration system composed of axial spring constant and rotor mass; Poor lubrication and bearing clearance caused by cylindrical rolling bearings or large diameter high-speed ball bearings.

4. Replacement of bearings: Apply appropriate axial spring preloading to adjust the bearing clearance, choose soft grease or grease with excellent low-temperature performance, and keep the residual clearance small (pay attention to temperature rise issues).

5. Method of rotor dynamic balance correction: After conducting dynamic balance measurement on the rotor of the dynamic balancing machine, the rotor can be balanced and processed using the weighting method and weight removal method as needed. The so-called weighting method is to install correction weights in the opposite direction of imbalance. Common methods include welding, soldering, riveting, screwing, and adding weight blocks. The weight removal method is to remove a certain amount of weight in the direction of imbalance. The commonly used methods include boring, drilling, chiseling, milling, grinding, etc.

36 Views