How to overcome the problem of dynamic balancing in a rotor balancing machine?

At present, there is very little interference in the process of measuring the unbalance of workpieces using a rotor balancing machine, and the detection system has high accuracy and efficiency; It is particularly suitable for dynamic balancing in the production process of rotating mechanical parts and plays an important role in workpiece dynamic balancing. However, there are still a series of issues with the process balancing method.

1. Balancing machines, especially high-speed ones, are too expensive.

2. When the rotor is in dynamic balance, the shutdown time is very long and slow, resulting in loss of balance.

3. Due to the limited number of rotors of different sizes and weights, it is difficult (if not impossible) to balance the crane.

For example, high-power steam turbine rotors and large ones without corresponding large balancing devices often result in imbalance; The main frame of a high-temperature steam turbine rotor is usually prone to elastic deformation, and when you stand up, it will automatically disappear. The rotor dynamic balance and thermal balance are obviously unbalanced machines.

4. After installation, dynamically balance the rotor to maintain good balance and ensure accuracy. Due to different support conditions for dynamic balancing rotors, different coordination and balancing rotors, rotor shafts, and equipment are supported. Even after they leave the factory, a high-precision file for dynamic balancing of the balancing rotor is established. The use of transportation and assembly precision balancing work inevitably plays a role, and vibration is not allowed.

In order to overcome the above process balancing method, the dynamic balancing machine technician proposed a dynamic balancing method.

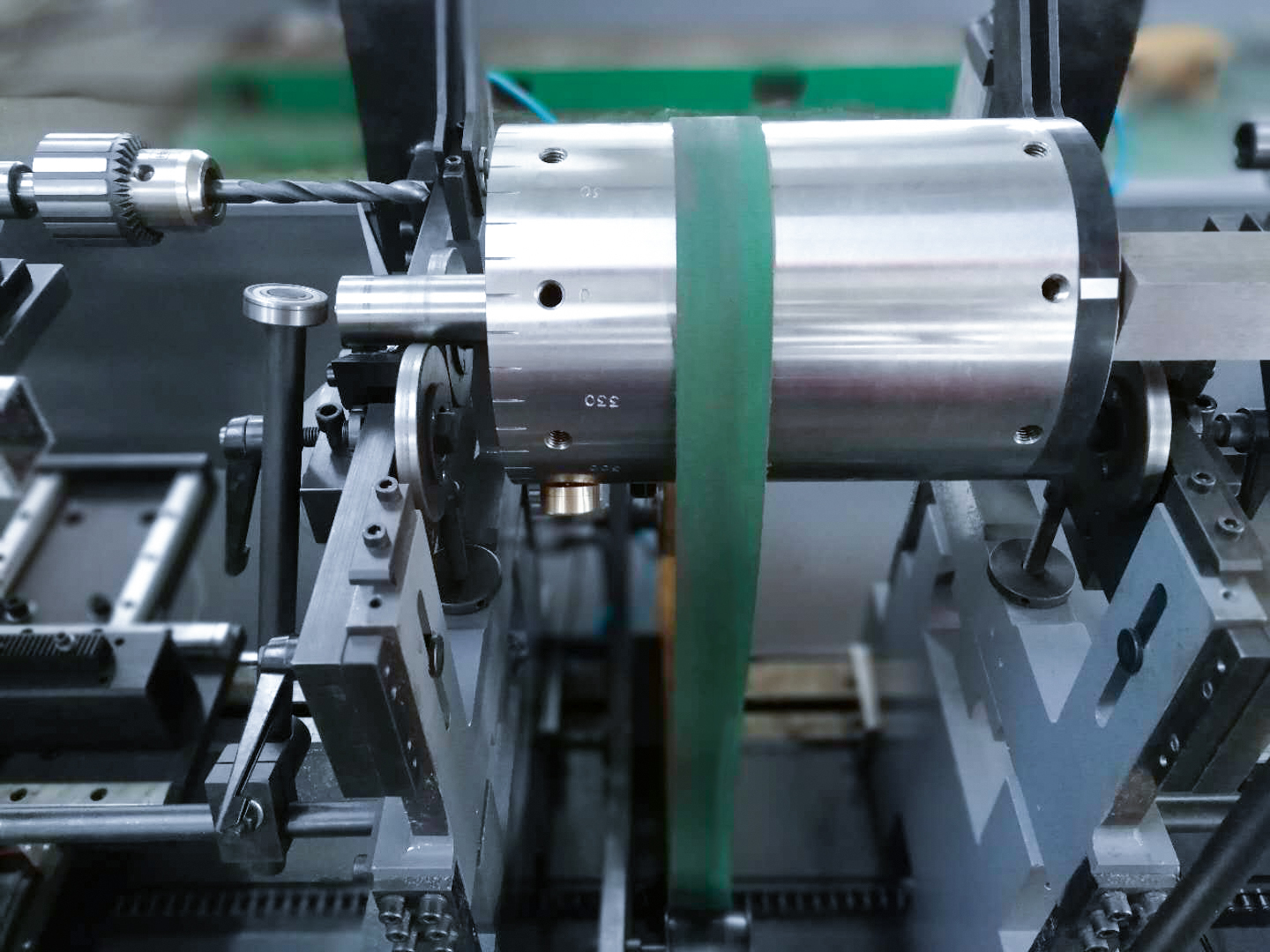

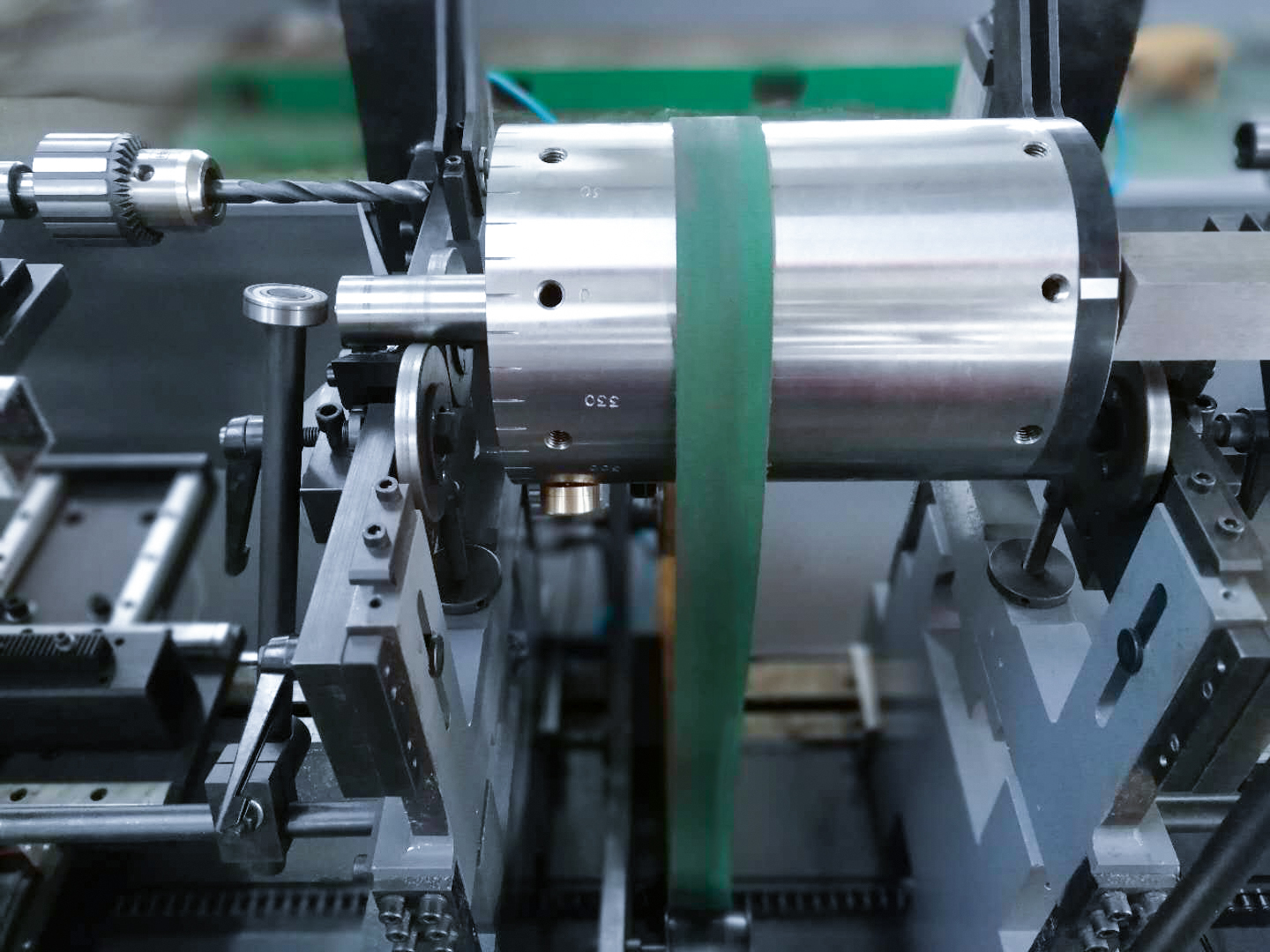

The dynamic balancing method described in the assembly operation of a rotating machine is a high-precision dynamic balancing method that uses sensors of a dedicated dynamic balancing machine to process the information of the vibrating part of the rotor, accurately determine the position of the rotor unbalance, and eliminate the unbalance to the standard state.

We also provide comprehensive balance detection technology and solutions, as well as high-quality balance detection equipment. The high-quality balance detection system can not only meet the requirements of any balance machine, but also accurately and quickly print the detected data for easy traceability and analysis of manufacturers.

The application scope of rotor balancing machine involves mechanical manufacturing such as motors, metallurgy, fans, crankshafts, transmission shafts, and household appliances. We are a high-tech enterprise dedicated to the research and development, design, production, and sales of dynamic balancing machines. Our main products include on-site balancing instruments, ring belt balancing machines, universal joint balancing machines, vertical balancing machines, horizontal balancing machines, spindle balancing machines, and specialized balancing machines.

At present, there is very little interference in the process of measuring the unbalance of workpieces using a rotor balancing machine, and the detection system has high accuracy and efficiency; It is particularly suitable for dynamic balancing in the production process of rotating mechanical parts and plays an important role in workpiece dynamic balancing. However, there are still a series of issues with the process balancing method.

1. Balancing machines, especially high-speed ones, are too expensive.

2. When the rotor is in dynamic balance, the shutdown time is very long and slow, resulting in loss of balance.

3. Due to the limited number of rotors of different sizes and weights, it is difficult (if not impossible) to balance the crane.

For example, high-power steam turbine rotors and large ones without corresponding large balancing devices often result in imbalance; The main frame of a high-temperature steam turbine rotor is usually prone to elastic deformation, and when you stand up, it will automatically disappear. The rotor dynamic balance and thermal balance are obviously unbalanced machines.

4. After installation, dynamically balance the rotor to maintain good balance and ensure accuracy. Due to different support conditions for dynamic balancing rotors, different coordination and balancing rotors, rotor shafts, and equipment are supported. Even after they leave the factory, a high-precision file for dynamic balancing of the balancing rotor is established. The use of transportation and assembly precision balancing work inevitably plays a role, and vibration is not allowed.

In order to overcome the above process balancing method, the dynamic balancing machine technician proposed a dynamic balancing method.

The dynamic balancing method described in the assembly operation of a rotating machine is a high-precision dynamic balancing method that uses sensors of a dedicated dynamic balancing machine to process the information of the vibrating part of the rotor, accurately determine the position of the rotor unbalance, and eliminate the unbalance to the standard state.

We also provide comprehensive balance detection technology and solutions, as well as high-quality balance detection equipment. The high-quality balance detection system can not only meet the requirements of any balance machine, but also accurately and quickly print the detected data for easy traceability and analysis of manufacturers.

The application scope of rotor balancing machine involves mechanical manufacturing such as motors, metallurgy, fans, crankshafts, transmission shafts, and household appliances. We are a high-tech enterprise dedicated to the research and development, design, production, and sales of dynamic balancing machines. Our main products include on-site balancing instruments, ring belt balancing machines, universal joint balancing machines, vertical balancing machines, horizontal balancing machines, spindle balancing machines, and specialized balancing machines.

1 Views