With the advent of Double 11, various industries have joined the wave of online selling and online shopping, and many machine manufacturers are also preparing to purchase dynamic balancing machines online. However, the purchase of balancing machines is also a big issue for many enterprises, which needs to be considered from various aspects. Which is the best balancer and what should be paid attention to when purchasing a dynamic balancer? The final decision can only be made after repeated comparison and consideration.

Some matters needing attention in purchasing balancer are shared with our master technicians in Shenman Dynamic Balancer Factory:

1. Measurement accuracy of dynamic balancing machine

We first need to look at the measuring accuracy of the dynamic balancing machine and see if there are any errors, because the errors are very annoying when measuring. The connection between the drive shaft and the balancing machine and the processing accuracy of the host are the main factors affecting the errors.

2. Selection of Base of Dynamic Balancer

The heavier the base weight of the hard-supported balancing machine, the better the base quality, and there is no influence on the balance accuracy. But it mainly affects weight loss. To achieve the same weight loss rate, you can use bulky or optional bases.

3. Dynamic balancing machine is divided into two support modes

Compared with soft support and hard support, the swing of soft support balancer is relatively soft. During start-up and stop of the drive shaft, the swing frame with soft support will have very obvious vibration, while the swing frame with hard support will not. Soft support and hard support are only negligible factors affecting the balance accuracy.

4. Characteristics of soft and hard supports

With a soft-supported balancer, the speed must be more than three times the resonance speed to be detected, so generally a higher speed is used, while a hard-supported balancer, whose speed must be less than three times the resonance speed, generally uses a lower speed.

5. Excellent measuring system

For the balancer, the measuring system is an important point of the whole balancer. The mechanical system design mainly considers the mechanical characteristics of the unbalanced vibration system, the support mode of the rotor, the driving mode and the conversion mode of mechanical vibration and electric energy.

The imbalance of rotor is transformed into electrical signal by sensors without distortion for measurement system to test. Due to unavoidable mechanical interference, the imbalance includes not only main vibration but also interference vibration when actual swing frame vibration occurs. Because it is in the case of small imbalance, this kind of chaotic interference is stronger than the main signal, so these strong interference signals will measure the weak imbalance signal, so the designed measuring system also needs to have excellent frequency selective filtering performance.

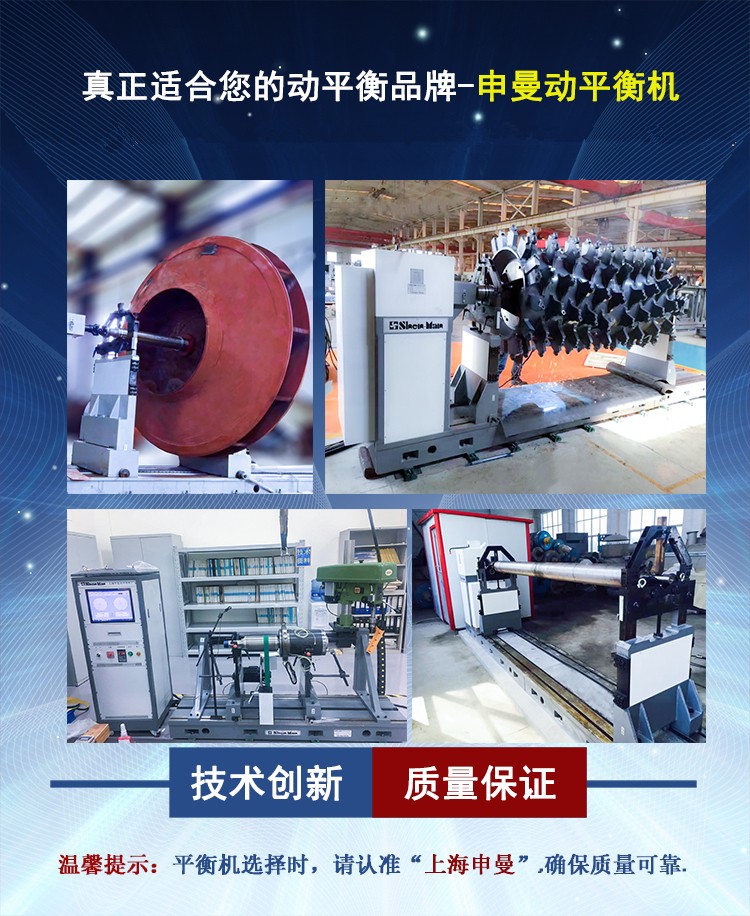

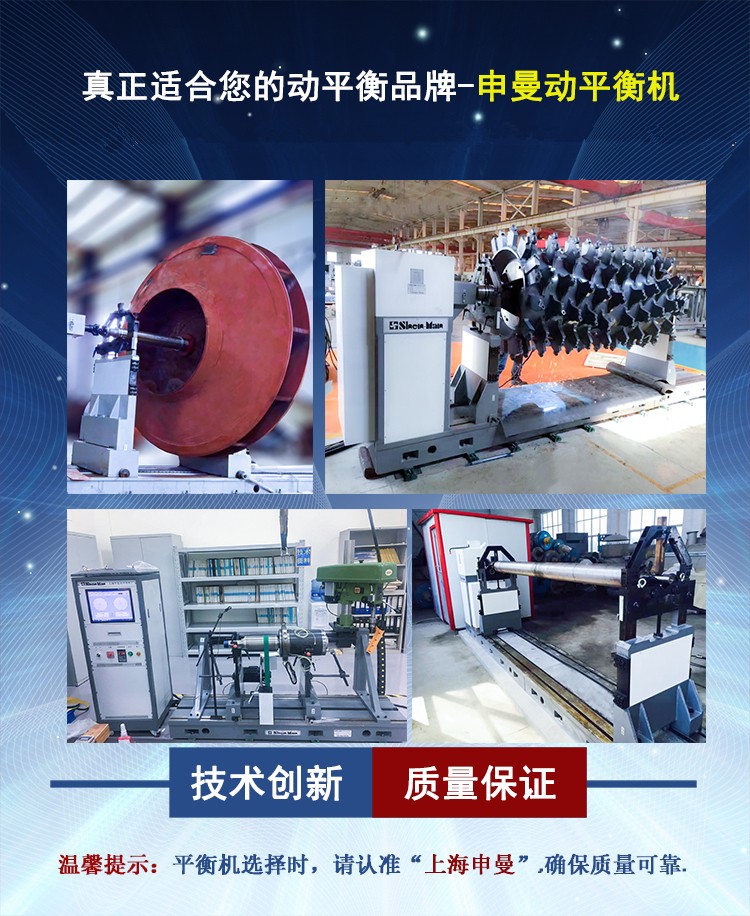

Established in 2002, Shanghai Shenman Electrical and Mechanical Equipment Co., Ltd. is a famous dynamic balancing machine manufacturing enterprise and balance testing equipment supplier in China. Its main business is self-driven balancing machine, automatic positioning balancing machine, vertical balancing machine, on-site balancer, balancing machine, ring balancing machine, dynamic balancing machine, automatic balancing machine, drive shaft balancing machine, cardan joint balancing machine, etc. It is one of the earlier private enterprises in China that has the capacity to produce 40 ton dynamic balancing machine, and at the same time, it is one of the enterprises that keep the private dynamic balancing machine breaking the production record of 70 ton dynamic balancing machine. For more information and prices on the balancing machine, please contact us!

Some matters needing attention in purchasing balancer are shared with our master technicians in Shenman Dynamic Balancer Factory:

1. Measurement accuracy of dynamic balancing machine

We first need to look at the measuring accuracy of the dynamic balancing machine and see if there are any errors, because the errors are very annoying when measuring. The connection between the drive shaft and the balancing machine and the processing accuracy of the host are the main factors affecting the errors.

2. Selection of Base of Dynamic Balancer

The heavier the base weight of the hard-supported balancing machine, the better the base quality, and there is no influence on the balance accuracy. But it mainly affects weight loss. To achieve the same weight loss rate, you can use bulky or optional bases.

3. Dynamic balancing machine is divided into two support modes

Compared with soft support and hard support, the swing of soft support balancer is relatively soft. During start-up and stop of the drive shaft, the swing frame with soft support will have very obvious vibration, while the swing frame with hard support will not. Soft support and hard support are only negligible factors affecting the balance accuracy.

4. Characteristics of soft and hard supports

With a soft-supported balancer, the speed must be more than three times the resonance speed to be detected, so generally a higher speed is used, while a hard-supported balancer, whose speed must be less than three times the resonance speed, generally uses a lower speed.

5. Excellent measuring system

For the balancer, the measuring system is an important point of the whole balancer. The mechanical system design mainly considers the mechanical characteristics of the unbalanced vibration system, the support mode of the rotor, the driving mode and the conversion mode of mechanical vibration and electric energy.

The imbalance of rotor is transformed into electrical signal by sensors without distortion for measurement system to test. Due to unavoidable mechanical interference, the imbalance includes not only main vibration but also interference vibration when actual swing frame vibration occurs. Because it is in the case of small imbalance, this kind of chaotic interference is stronger than the main signal, so these strong interference signals will measure the weak imbalance signal, so the designed measuring system also needs to have excellent frequency selective filtering performance.

Established in 2002, Shanghai Shenman Electrical and Mechanical Equipment Co., Ltd. is a famous dynamic balancing machine manufacturing enterprise and balance testing equipment supplier in China. Its main business is self-driven balancing machine, automatic positioning balancing machine, vertical balancing machine, on-site balancer, balancing machine, ring balancing machine, dynamic balancing machine, automatic balancing machine, drive shaft balancing machine, cardan joint balancing machine, etc. It is one of the earlier private enterprises in China that has the capacity to produce 40 ton dynamic balancing machine, and at the same time, it is one of the enterprises that keep the private dynamic balancing machine breaking the production record of 70 ton dynamic balancing machine. For more information and prices on the balancing machine, please contact us!

185 Views