Dynamic balance detection and correction of motor rotor is an effective method to reduce operating noise of motor. In the process design of rotor dynamic balance correction, it is the key to determine the total residual unbalance of motor rotor and distribute the total residual unbalance to several correction planes.

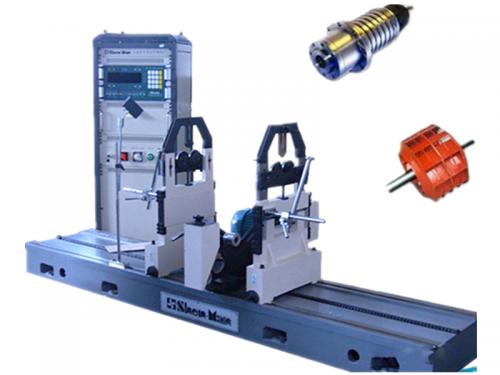

The dynamic balance tester can be used for matching the production of the dynamic balancing machine, retrofitting the old dynamic balancing machine and performing on-site dynamic balance test. In recent years, with the development of science and technology in mechanical industry, the rotating speed of rotating machinery is getting higher and higher. People have higher and higher requirements on the vibration and other performance of such products. The important way to improve this performance is to improve the accuracy and efficiency of dynamic balance. This instrument has been successfully developed in response to this situation. The instrument is characterized by high accuracy, high accuracy, simple operation and easy maintenance. All the instruments are controlled by integrated circuits and the latest single-chip computer. Among them, automatic tracking filter technology, automatic compensation technology, program control technology and self-learning technology are adopted with stable performance.

Commonly used machines contain a large number of rotating parts, such as various drive shafts, spindles, motors and turbine rotors, which are collectively called gyroscopes. Ideally, the pressure on the bearings is the same when the body rotates as when it does not, and such a body is a balanced body. However, due to uneven material or blank defects, errors in processing and assembly, asymmetric geometry and other factors in design, all kinds of revolving bodies in engineering can not cancel out centrifugal inertia forces generated by each small particle on the revolving bodies. Centrifugal inertia forces cause vibration, noise and accelerated bearing wear through bearing acting on the machinery and its foundation. It shortens the mechanical life and can cause destructive accidents in severe cases. To do this, the rotor must be balanced to a level of allowable balancing accuracy or the resulting mechanical vibration amplitude must be reduced within the allowable range.

In modern times, there are many balancing methods used for all kinds of machines, for example, one-sided balancing (also called static balancing) usually uses balancing frame, and two-sided balancing (also called dynamic balancing) uses all kinds of dynamic balancing test machines. The static balancing accuracy is too low and the balancing time is too long. Although the dynamic balancing tester can balance the rotor itself well, when the dimensions of the rotors are quite different, the dynamic balancing testers of different sizes are often required, and the rotors still need to be removed from the machine during the test, which is obviously neither economical nor labor-intensive (e.g. the turbine rotors after overhaul). In particular, the dynamic balancing machine can not eliminate the system vibration caused by assembly or other follower elements. Balancing the rotor under normal installation and operation conditions is often referred to as "on-site balancing". Field balancing can not only reduce the labor of disassembling and assembling the rotor, but also eliminate the need for dynamic balancing machine. At the same time, the test state is identical with the actual working state, which is beneficial to improve the accuracy of measuring imbalance and reduce system vibration. International standard ISOl940-1973 (E) "Balance accuracy of rigid body rotator" stipulates that precision rotors with balance accuracy of G0.4 must be balanced on site, otherwise the balance is meaningless. In equipment maintenance, the whole machine dynamic balance technology on-site shows its superiority. Because the rotor will inevitably result in permanent deformation of varying degrees after running at high speed for a long time; Friction and wear, etc., all of which will result in a reduction in the balance accuracy. An effective way to solve these problems is to balance the rotating machinery on-site. In addition, the fault diagnosis of rotating machinery can also be carried out by using dynamic balance method on-site of the whole machine combined with conventional detection methods.

270 Views