details

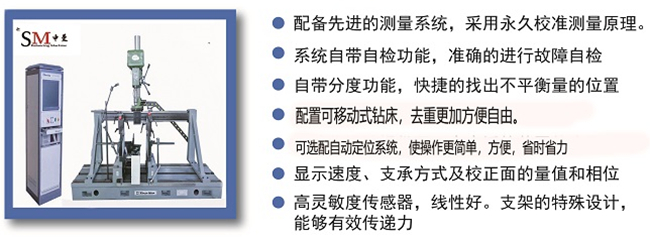

SA-8D horizontal automatic weight-removal balancer is mainly used for weight-removal of drums and motors. Fully automatic balancer in Shenman Dynamic Balancer Plant is gradually becoming an indispensable mechanical equipment for all kinds of rotors and work pieces requiring dynamic balance correction. For example, motor rotor, rubber bar, supercharger rotor, inertial flow air-conditioning blade, axial fan, woodworking cutter, wooden knife, flywheel, micro-motor grinding wheel, brake drum, bull blade, pump blade, internal combustion engine, drum washer rotor, rotary cup, mining machinery, textile machinery and other fields are widely used.

Fully automatic double-sided horizontal dynamic balancer is a balancer which simplifies the measurement and correction of rotor imbalance to specific two correction planes by utilizing the principle of two-sided balancing of rigid rotors. Two mechanical solutions of double-sided hard-supported dynamic balancing machine are influence coefficient method and ABC method. The ABC method is easy to operate. As long as each dimension of A, B and C is measured, the plane separation circuit is corrected and set up.

Replacing traditional dynamic balancing machine with automatic balancing machine can not only greatly improve production efficiency and product quality, improve enterprise market competitiveness, but also effectively liberate labor productivity, reduce labor intensity of operators, reduce staffing and save manpower, material and financial resources. Compared with other common equipment used in centrifugal force measurement of rotor, the automatic positioning dynamic balancing machine has the advantages of no marking, operator finding unbalance angle, high measuring accuracy, strong repeatability, short measuring time, etc., fully embodying its intelligence and realizing efficient, economical and flexible intelligent production.

Main technical parameters and configuration of horizontal automatic de-weighing balancer equipment:

1. Maximum mass of workpiece: 500kg

2. Maximum diameter of workpiece: 1260mm

3. Shaft diameter range at ring belt drive: 20-450mm (steel, strength according to 500KG)

4. Distance between two supports: 300-3000mm (total length of bed L=4000mm,)

5. Support shaft diameter range: 9-90, 90-180 mm

6. Balance speed: 180-1000 (variable frequency speed adjustment,)

7. Motor power: 4 kW

8. Minimum achievable residual unbalance: ≤0.5 (g.mm/kg)

9. Reduction rate of unbalance: ≥95%

10. Electric measuring box adopts computer touch screen: 17 inch LCD display

11. Power supply configuration: 3-phase, 380V, 50HZ

12. Operating system selection: Windows XP system (original Yanhua Industrial Control System)

13. Local area network with USB interface and man-machine conversation

14. Ceramic Piezoelectric Sensor, Infrared Photoelectric Optical Fiber Sensor: Beijing Aerospace

15. Bearings in rollers: NSK (Japan)

16. Siemens is used as main electronic and electrical components

17. Distribution Inverter: 4 KW

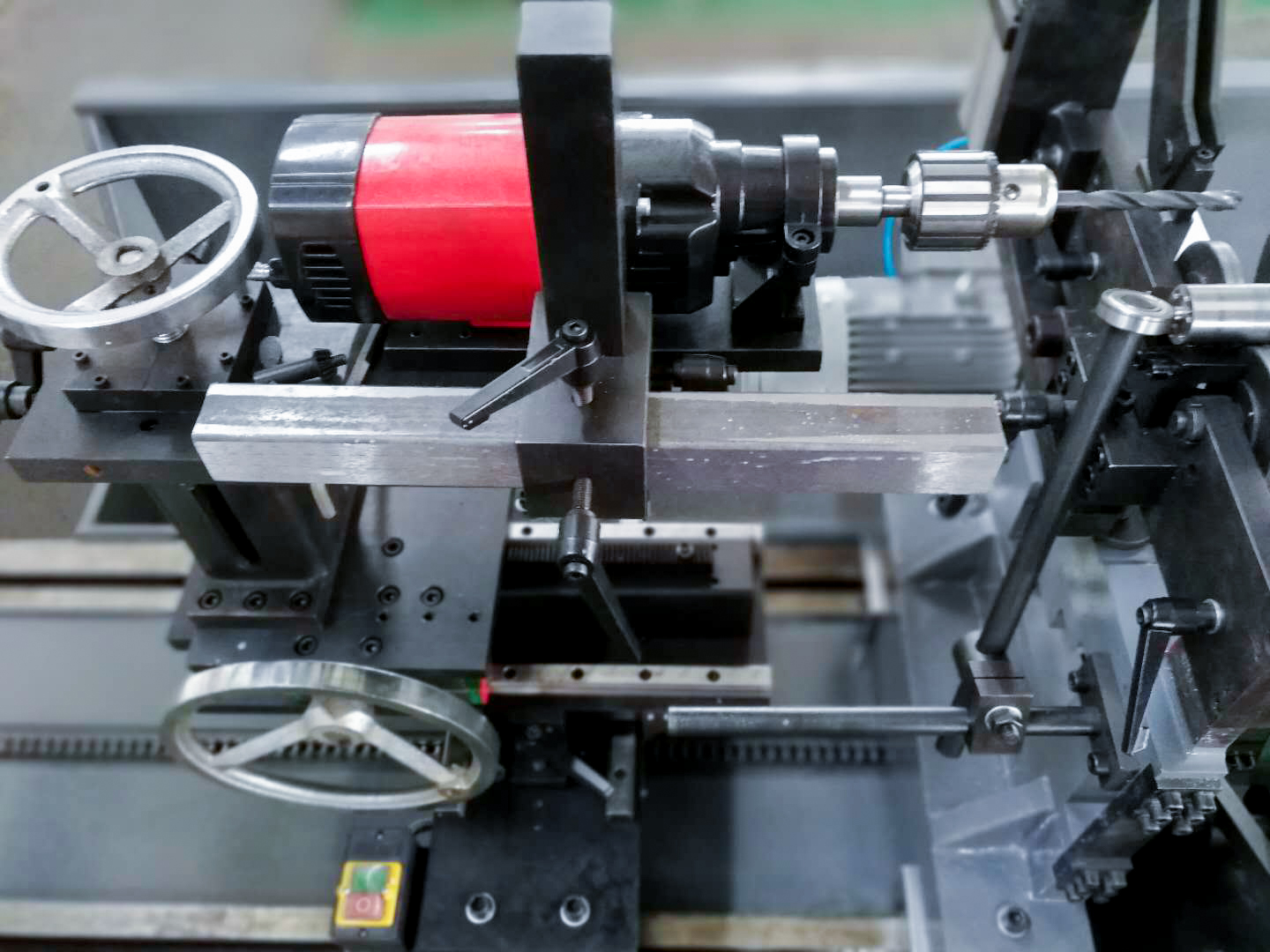

18. When a bench-type manual magnetic drill bit (drill bit can be loaded and unloaded) is equipped at the left and right ends of the bed to remove the maximum diameter of 6-12mm (complete the holder, do not run angle) and then to remove the weight, start the button, lock the weight-removed workpiece (prevent the running angle of workpiece), then the opposite side of the weight-removed workpiece is equipped with jacking device (prevent the workpiece from moving left and right).

19. Equip with a set of manual grinder

20. Equip an A4 printer to print data report easily

21. Install encoder with light needle display to find out imbalance position quickly

22. The system has its own self-test function to check faults accurately

23. Provide 6 kinds of support methods to choose, which are suitable for balanced measurement of workpiece with different support methods.