details

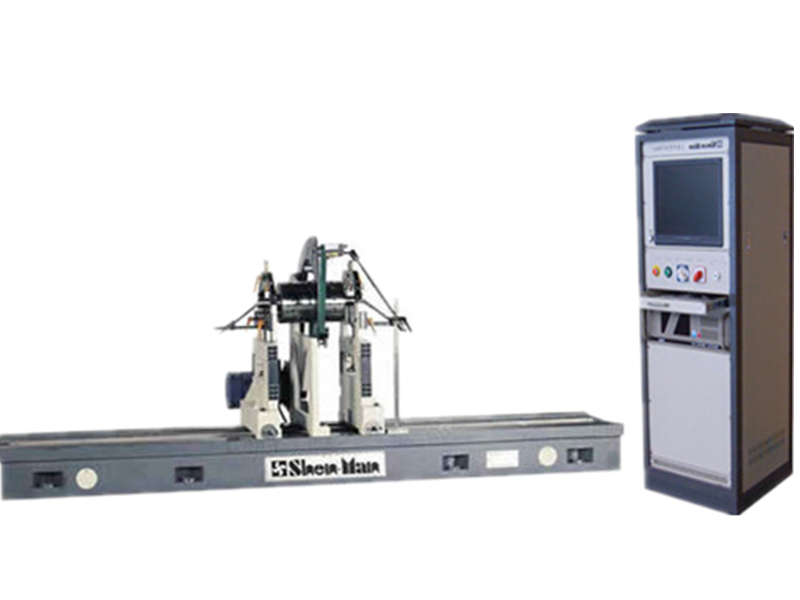

Sa-7 (300kg) is one of the balance machine series of the company's belt drive,Mainly used in large motor, ceramic machinery, roller, glue stick, fan, shaft and other rotating body workpiece balance check.

Measurement system adopts SMC microcomputer measurement system. Speed, value and phase are all digitally displayed. Unbalance is directly displayed by "G". Six types of rotor can be arbitrarily selected, directly with digital input of various parameters, after a start can correctly display the value of the unbalance of the workpiece (G) and phase, and can store data and display intuitive. The belt is adopted as the transmission mode, so it is easy to load and unload and fast to start.

The electromechanical transducer adopts piezoelectric sensor, which has the advantages of small volume, large output and high sensitivity.

| SA-7(300kg)Hard Bearing Belt Drive Balancer Technical Parameters: | |

| 1. Maximum mass of workpiece(kg) | 300 |

| 2. Maximum diameter of work(mm) | 1260 |

| 3. Axle diameter range at belt drive(mm) | 20-450 |

| 4. Distance between two supports(mm) | 170-2500 |

| 5. Range of bearing diameter(mm) | 10-180 |

| 6. Balancing speed(r/min) | Drag the diameter to 100mm 860/1230/1720/2460 |

| 7. Motor Power(kw) | 1.3/1.8 |

| 8. The minimum residual unbalance can be achieved emar(g﹒mm/kg) | ≤0.5 |

| 9. Unbalance reduction ratio URR(%) | ≥95 |

| 10. Power Supply | three-phase/380V ; 50HZ |

| 11. Equipped with independent vertical control cabinet | |

| 12. Electrical measuring box |

|

| 13.滚轮架中轴承 | NSK(Japan) |